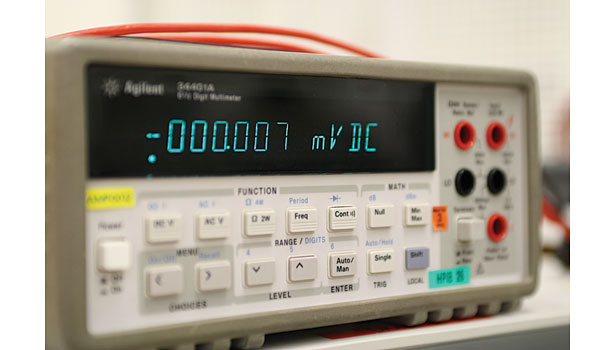

Equipment calibration deals with assessing the accuracy of equipment s results by measuring the variation against a defined standard to decide upon the relevant correction factors.

Calibration of equipment in fitness testing.

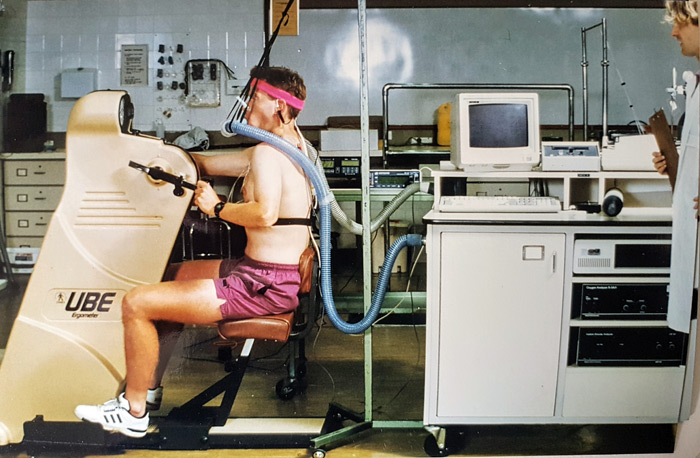

All fitness testing equipment require regular calibration other equipment requiring regular calibration vo2max equipment stringent calibration of the equipment is necessary for both the expired gas and ventilation measurement systems.

Equipment used infrequently such that the manufacturers recommendations cannot be followed shall have calibration verified prior to use.

Otherwise you are calibrating within overlapping tolerances and the tolerances of your standard render an in cal instrument out of cal or vice versa.

Prior to being used in testing new equipment or any piece of equipment which leaves the control of the laboratory shall undergo calibration procedures or performance verification.

Note that the evaporation of moisture on the temperature sensor or do probe may influence the readings during calibration.

The calibration procedure should specify where to place the load during the test and calibration results in certificate format should also document the locations.

Let s look at how that works.

The test load used in an eccentricity test should be at least one third 1 3 of the max load of the weighing instrument.

Calibration standards used for inspection measuring and test equipment shall be traceable to national or international standards.

If you reserved calibrated test instruments for a critical test it is best practice to send that same equipment for calibration after the testing.

If national or international standards are not practical or.

Weight measurement weight measurement scales should be checked it see if they are accurate.

The equipment is accordingly adjusted to fine tune its performance to tally with accepted standard or specification.

Calibration typically requires a standard that has at least 10 times the accuracy of the instrument under test.